The non-renewable nature of bitumen and its increasing consumption pose a significant challenge in infrastructure development, particularly in constructing and maintaining asphalt roads. To address this issue, sustainable approaches are essential. Substantial efforts have been made to enhance the resilience, sustainability, and circular nature of asphalt pavements. One promising solution is the use of bio-based materials. This article provides a comprehensive review of the current advancements in bio-bitumen development, focusing on wood-based oils, waste cooking oils, and bio-bitumen from manure. It is evident that bio-oils currently used are more effective as additives, such as softeners, rejuvenators, or modifiers, rather than as full replacements for binders. One of the most promising roles for bio-oils is as rejuvenators, with potential antioxidant properties. Incorporating polymers into bio-oils is another viable method to improve bio-bitumen’s performance. However, caution is needed when producing bio-bitumen due to potential compatibility issues that could affect performance, and this should be carefully managed.

1. Introduction

Bitumen, a by-product of refining petroleum, has been widely used since its discovery. Over time, its applications have grown alongside technological advancements. Today, asphalt plays a key role in industries like road construction, building, and waterproofing roofs. A significant portion of the world’s bitumen production is dedicated to road construction and maintenance, solidifying its leading role in the construction sector. However, the finite nature of bitumen, alongside declining global petroleum reserves and external market pressures, has led to a continuous increase in bitumen prices. This situation has profoundly impacted the road construction industry, where the demand for asphalt pavements is rising in parallel with bitumen usage. The growing mismatch between supply and demand has made it crucial to find greener, renewable, and cost-effective alternatives to petroleum-based bitumen.

In recent years, bio-oils have gained significant interest from researchers due to their plentiful supply, renewability, and low cost. Bio-oil is derived from biomass, including wood, agricultural residues, animal manure, and used cooking oil, through processes such as pyrolysis, hydrothermal liquefaction, and plasma electrolytic liquefaction. The main elements found in bio-oil—carbon, hydrogen, oxygen, and nitrogen—are similar to those in petroleum-based bitumen, along with certain bonding and viscoelastic properties. Bio-oils are viewed as potential binders for road applications, with the potential to partially or fully replace petroleum bitumen.

2. Wood-Based Bio-Bitumen

Among various biomass sources, wood biomass is plentiful and accessible, with timber, discarded wood products, and sawdust providing reliable materials for producing pyrolysis oil. These resources can often be sourced locally. Researchers have investigated the physical and chemical properties of different wood-based bio-oils, focusing on their use as additives to enhance bitumen performance, rejuvenate aged bitumen, and improve resistance to aging. Some progress has been made in these areas.

However, challenges remain. High levels of light and volatile components, weak resistance to deformation at high temperatures, and high sensitivity to aging limit the current effectiveness of bio-oil applications. The replacement rate of bio-oils for petroleum bitumen remains low, and numerous technical hurdles must be overcome before bio-bitumen can fully replace its petroleum counterpart.

2.1. Wood-Based Bio-Oil Production for Bitumen Modification

Wood-based bio-oil is created by chemically processing wood materials like logs and sawdust to break down organic polymers such as cellulose, hemicellulose, and lignin. These intermediate products undergo various physical and chemical changes to produce a dark, viscous liquid. Pyrolysis is currently the most widely used method for producing bio-oil, given its similarity to petroleum refining systems. This process can be further categorized into thermal cracking methods based on the residence time of gases generated during pyrolysis.

Fast pyrolysis, which yields high quantities of bio-oil and meets the demand for binding materials in road construction, is the most common method used in this field. Fast pyrolysis involves heating dried biomass in an oxygen-free environment at very high temperatures (400-550°C), causing rapid cracking and producing bio-oil in a matter of seconds.

2.2. Characteristics and Enhancements of Wood-Based Bio-Oil

Like petroleum asphalt, wood-based bio-oil is primarily composed of carbon, hydrogen, oxygen, and nitrogen, with slight variations based on the biomass source. Studies indicate that bio-oil generally contains higher oxygen levels, lower carbon content, and a lower hydrogen-to-carbon ratio compared to petroleum bitumen. These differences are due to the presence of oxygenated compounds formed during the breakdown of wood polymers like cellulose and lignin. These compounds, along with the presence of water, contribute to bio-oil’s susceptibility to aging.

Wood-based bio-oil is a complex mix of water, soluble and insoluble organic compounds, including acids, alcohols, aldehydes, esters, and phenols. It contains over 400 identified compounds, though this number is not exhaustive due to technological limitations in identifying all constituents. Water, which makes up 20-40% of bio-oil, significantly affects the performance of bio-asphalt, necessitating extensive water separation processes before bio-oil can be used as a binder.

By employing distillation and other techniques to reduce water content, researchers have successfully concentrated bio-oil’s usable components, resulting in a product known as “bio binder.” However, even after water removal, bio binder still differs significantly from petroleum bitumen in terms of chemical composition, with notable differences in resin, aromatic, and asphaltene content. These variations play a crucial role in the differences between bio-oil and petroleum bitumen’s rheological properties.

2.3 Potential for Substituting Bitumen with Wood-Derived Bio-Oil

The chemical makeup and rheological traits of bio-binders closely resemble those of petroleum bitumen, making it a promising candidate for complete replacement. If a suitable bio-binder derived from wood could be developed to serve as the primary binding material for flexible pavements, it could significantly advance sustainable road construction. Consequently, many studies have been carried out to assess whether bio-binders can fully take the place of petroleum bitumen.

Binder properties play a pivotal role in determining the performance of road mixtures and structures. To maintain the durability of asphalt pavements and prevent early binder failure, road engineers have proposed various performance indicators from different angles. These indicators help mitigate potential issues with petroleum bitumen, including high-temperature, low-temperature, fatigue, and aging-related failures. Since research on bio-binders for road construction is relatively new, studies on bio-binder performance in roads have mostly relied on established methods and tools originally developed for petroleum bitumen.

Although using wood-based bio-binders directly in road engineering is still rare, laboratory research has revealed several limitations when employing these materials for flexible pavements. Therefore, it is reasonable to conclude that, particularly in their pure form, bio-binders are not yet capable of fully replacing petroleum bitumen.

One notable drawback is that wood-based bio-binders generally have lower viscosity and exhibit a narrower viscous temperature range—about 30°C to 40°C less than petroleum bitumen. Additionally, bio-binders display higher sensitivity to temperature and shear rates, which can lead to shear thinning. Even with improvements made to bio-binders from oak wood, their dynamic shear modulus, rutting resistance, and elastic recovery remain relatively low, and their high-temperature performance grade is below 40°C. To tackle this poor performance at elevated temperatures, researchers have applied modification techniques from the bitumen industry, blending common additives like SBS, rubber particles, and terpolymers with bio-binders to improve their heat stability. Research suggests that the presence of more light components in bio-binders aids in better swelling and distribution of these additives. The inclusion of appropriate modifiers may thus represent a crucial strategy in achieving the complete replacement of petroleum asphalt by bio-binders in the future.

A notable field study compared the structural and roughness performance of conventional petroleum-based asphalt (HMA) and bio-binder pavement (BM) over three years. The results indicated that bio-binder pavement performed comparably to its petroleum counterpart, showcasing the potential of using suitable modifiers to enhance bio-binders and possibly replace petroleum bitumen.

During pavement construction and use, binders naturally age. Therefore, in addition to evaluating fresh bio-binders, it’s essential to examine their performance after aging, particularly in terms of low-temperature durability and fatigue resistance. One study compared the dynamic shear modulus of pine resin bio-binder and petroleum bitumen before and after short-term aging. The findings revealed that, at both higher and lower frequencies, aged bio-binder showed a greater increase in dynamic shear modulus compared to aged petroleum bitumen. Moreover, aged bio-binders were more rigid and brittle than their petroleum counterparts. Despite this rigidity improving high-temperature performance, it adversely affected bio-binder’s fatigue resistance.

The tendency of bio-binders to age quickly is linked to the higher concentration of light components in their composition. Bio-binders contain a significant portion of volatile light components, with up to 40% evaporating at temperatures around 290°C. Testing has shown that these components have low molecular weights, contributing to the brittle nature of the residual material. Additionally, the lower molecular weights (Mn, Mw, Mz) in bio-binders compared to petroleum bitumen further contribute to aging issues. The higher oxygen content in bio-binders also exacerbates their susceptibility to aging, though a comprehensive understanding of how bio-binders age on multiple levels remains lacking.

2.4 Utilization of Wood-based Bio-binder as a Modifier

While bio-binders can sometimes match or even surpass certain properties of petroleum bitumen, only a few bio-binders currently satisfy the evaluation criteria required for petroleum bitumen substitutes. Consequently, the most prevalent use of wood-derived bio-binder in road construction is as an additive, replacing a portion of petroleum bitumen. This blend of bio-oil and petroleum bitumen is often termed bio-bitumen.

For bio-bitumen to provide satisfactory road performance, similar to polymer-modified bitumen, a key factor is the compatibility between bio-oil and petroleum bitumen, which should form a stable, homogeneous mixture. One study evaluated the molecular compatibility between wood-based bio-binder from Michigan and petroleum bitumen using the Automatic Flocculation Titration (AFT) technique to examine their miscibility. It found that with 2% bio-oil content, the two materials were stable and compatible. However, it is hypothesized that higher bio-oil content would reduce compatibility, though no studies have been conducted on mixtures with a higher concentration of bio-oil.

Another method, the ASTM D7131 standard, was used to assess the separation of bio-binder and petroleum bitumen in bio-bitumen by observing the difference in rutting factors between the top and bottom sections of a sample. When the bio-binder content reached 50%, the rutting factors showed significant discrepancies between the sections, indicating a drop in compatibility. Studies also analyzed the thermal stability of bio-bitumen with varying bio-binder content, ranging from 10% to 30%. The results showed lower thermal stability for bio-bitumen compared to base bitumen, with significant differences in softening points, viscosity, and rutting factors between the upper and lower portions after storage, particularly as bio-binder content and storage time increased.

To conclude, current research on the compatibility between bio-binder and petroleum bitumen is limited. Claims of “good compatibility” based on elemental or rheological similarities have not been sufficiently validated in practice. Studies indicate that at higher bio-binder contents, compatibility weakens. Therefore, it is critical to develop multi-scale characterization techniques for their compatibility and propose technical solutions to improve their performance.

A key question remains whether chemical reactions occur when bio-oil and petroleum bitumen are blended, and how this impacts the colloidal structure of the resulting bio-bitumen compared to petroleum bitumen. Some researchers have explored this by analyzing changes in functional groups using Fourier-transform infrared spectroscopy. They found alterations in the absorption peaks of certain compounds, though it’s uncertain whether these changes result solely from chemical reactions or other factors like the volatility of compounds during blending. Similarly, another study indicated that while there were noticeable shifts in certain spectral peaks, no significant chemical reactions seemed to occur when bio-oil and petroleum bitumen were mixed.

As a result, researchers typically attribute performance changes in bio-bitumen to alterations in colloidal structure rather than chemical reactions. Bio-binder has lower levels of saturated fractions and asphaltene compared to petroleum bitumen. One study found that bio-bitumen containing 15% bio-oil had a significantly higher resin and aromatic fraction than petroleum bitumen, with corresponding reductions in the saturated fraction and asphaltene content. This suggests no chemical reactions occur during blending, further supporting the idea that changes are primarily physical.

The material characteristics of the chosen petroleum bitumen are crucial to these results. Therefore, using the performance grading system for petroleum bitumen as a reference for bio-binder may offer a more standardized approach. However, this also presents challenges. For example, the high-temperature grading system used for petroleum bitumen, which involves subjecting the material to an RTFOT test at 163°C for 80 minutes, may not be suitable for bio-binder, as it would cause significant aging due to bio-binder’s lower heat tolerance. Consequently, the current grading standards for petroleum bitumen are not directly applicable to bio-binder.

2.5 Wood-based Bio-oil as an Antioxidant in Bitumen

Despite bio-binder’s vulnerability to aging due to its high volatile content and elevated oxygen levels, research shows that bio-bitumen undergoes significantly less oxidative aging than petroleum bitumen. Specifically, after aging, bio-bitumen has lower aging indices, such as the carbonyl index and activation energy, compared to petroleum bitumen, suggesting it is more resistant to oxidative degradation. This reduced oxidative aging effect is linked to a lower ratio of polar to non-polar components in bio-bitumen.

The key role of specific phenolic compounds in mitigating the oxidative aging process is one reason why bio-binder might serve as an effective antioxidant in bitumen. These compounds can neutralize free radicals formed during the oxidation of petroleum bitumen, halting oxidation-related chain reactions. Phenolic compounds also help counteract aggregation during aging by reducing the increase in intermolecular forces caused by oxidation. Given that wood-based bio-binder contains many phenolic compounds, understanding the types of phenolic compounds in bio-oil and their antioxidant properties under different conditions is a promising research direction.

In addition to phenolic compounds, bio-oil contains carbon particles that can absorb UV light and scavenge free radicals, slowing down the photo-oxidative aging of bio-bitumen. Some researchers have also proposed that bio-binder contains highly reactive components, such as α-tocopherol, which act as sacrificial agents, protecting the more sensitive elements of petroleum bitumen from oxidation. Additionally, bio-binder’s molecular components are less polarizable than those in petroleum bitumen, further reducing their likelihood of developing new polar functions in the presence of oxidizing agents.

It is important to note that bitumen aging involves more than just oxidation. Other processes, such as chain scission, aromatization, aggregation, and the evaporation of volatile components, also play a role. As a result, when assessing bio-binder’s anti-aging effects using various indicators, its performance may vary. Furthermore, bio-bitumen still experiences the loss of light components through volatilization, especially when present in higher concentrations or in thin layers.

3 Vegetable Oil-Based Bio-Bitumen

Vegetable oils, extracted through either physical or chemical processes from various plants, come in two main categories: fresh vegetable oil and waste vegetable oil. Both types have the potential to modify petroleum-based asphalt or rejuvenate aged petroleum asphalt, as illustrated in Figure 1.

Vegetable oils are primarily composed of fatty acids (FAs) and triglycerides derived from glycerol. Common fatty acids include palmitic, stearic, oleic, linoleic, and linolenic acids. The unique properties of each vegetable oil are defined by its fatty acid profile, which greatly impacts the oil’s physical and chemical behavior, and thus its potential effects when combined with bitumen.

Soybean oil and its derivatives have been the subject of significant research in terms of their application in asphalt and bitumen mixtures. These oils have been tested in experimental road sections, where their long-term performance under various environmental and traffic conditions has been evaluated. Sunflower seed oil is another alternative that can be used in road engineering alongside soybean oil. Oils that contain higher amounts of oleic acid, known as high-oleic vegetable oils, exhibit better oxidative stability. The level of oleic acid purity in such oils influences the chemical, thermal, and rheological properties of polymers based on vegetable oils, impacting factors like viscosity, thermal resistance, and glass transition temperature.

However, using fresh vegetable oil as a binder in pavements is often considered wasteful, especially given the ongoing food scarcity in many parts of the world. Waste vegetable oil (WVO), a by-product created when fresh oil is subjected to high temperatures in cooking, is non-edible and has a darker color and higher viscosity than fresh oil. The characteristics of WVOs vary depending on the source, processing methods, and the type of food cooked in them. During the frying process, vegetable oils undergo changes like hydrogenation and oxidation, which alter the fatty acid profile from polyunsaturated to more saturated forms, alongside the creation of compounds like aldehydes and trans-fatty acids.

3.1 Waste Vegetable Oil as Rejuvenators

Traditional rejuvenators for bitumen, derived from heavy oil, replace the light components lost in aged asphalt. However, they tend to evaporate at high temperatures, reducing their effectiveness. In contrast, fresh and waste vegetable oils, primarily composed of triglycerides and unsaturated fatty acids, resemble the light fractions of bitumen and offer better temperature resistance. Classified as bio-rejuvenators, these oils are environmentally friendly, biodegradable, and cost-effective, making them an attractive alternative to traditional rejuvenators.

Many studies have explored the potential of vegetable oils as bio-rejuvenators to restore the properties of aged asphalt binders, focusing on aspects like rheological performance and low-temperature behavior. For instance, one study used waste vegetable oil from restaurants as a substitute for heavy oil and a commercial rejuvenator to treat aged asphalt from reclaimed asphalt pavement (RAP). Rheological properties were measured with a dynamic shear rheometer (DSR) and rotational viscosity tests, while the low-temperature performance was assessed with bending beam rheometer (BBR) tests. The results showed that vegetable oil rejuvenators effectively reduce the viscosity and stiffness of aged asphalt, improving fatigue resistance and crack performance at lower temperatures.

Other research examined the microstructure of aged asphalt treated with varying amounts of waste vegetable oil and different rejuvenation times, finding that adding WVO replenished saturates and aromatics, preventing their transformation into asphaltenes and resins. Optimal results were achieved with a rejuvenation time of 60 minutes and a 7% content of waste vegetable oil.

Additionally, studies have evaluated the impact of WVO viscosity on the recovery of aged bitumen’s performance. One investigation found that both extremely high and low viscosity levels in WVO negatively affected the rejuvenated bitumen’s properties. Meanwhile, another experiment using sunflower seed oil revealed that a 5% addition could recover 30% of the modulus loss in aged bitumen, showing its potential for restoring rheological performance.

On a microscopic level, aging leads to the oxidation of benzyl and sulfuric compounds in bitumen, transforming them into carbonyl and sulfoxide groups. Visibly, the honeycomb structure of the asphalt binder breaks down over time. However, adding plant-based oils can slow the oxidation process, helping restore this structure. Plant oils do not chemically interact with asphalt, but they replenish light components like saturates and aromatics, preventing further aging of the binder.

Compared to traditional rejuvenators, bio-rejuvenators offer greater stability and are less prone to high-temperature evaporation, which significantly improves the efficiency of the rejuvenation process.

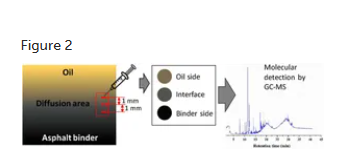

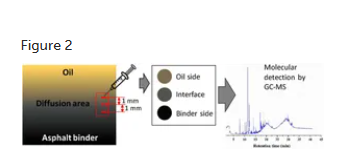

The Penetration Effect of WCO on Aged Asphalt

It is important to highlight that the penetration ability of WCO (waste cooking oil) rejuvenators on aged asphalt plays a crucial role in the effectiveness of asphalt regeneration. Research has demonstrated that when WCO is used to rejuvenate aged asphalt, it forms a diffusion area without a clear boundary, as depicted in Figure 2. Understanding the physicochemical characteristics of the binder at different points within this diffusion zone provides valuable insight into how WCO rejuvenators work. Xiao, through advanced techniques like interface image thresholding and tracer analysis, explored how bio-rejuvenators and aged bitumen interact at a microscopic scale. This research helped establish links between the microscopic and macroscopic properties of plant oil-rejuvenated asphalt, offering a deeper understanding of the modification process.

3.2 The Role of WVO in Bitumen Modification

Conventional bitumen often falls short of meeting the demands posed by heavy traffic and extreme weather. As a result, polymers and other additives are used to improve the performance of base bitumen, enhancing its rheological characteristics and extending the lifespan of pavements. Plant oils, recognized as eco-friendly alternatives, have been increasingly studied for their role in modifying bitumen.

The modification of bitumen with plant oil can be divided into three approaches: directly incorporating plant oil into base bitumen, combining it with other materials like plastics or rock bitumen, or using plant oil to activate other additives, thereby enhancing their effectiveness. Due to their similar chemical makeup, plant oils blend well with bitumen. The linear alkane structure of fatty acids in plant oil can lower the viscosity of base bitumen, improving its resistance to cracking at low temperatures. However, the introduction of light molecules may cause the bitumen to melt unevenly, which could negatively affect its ability to withstand high temperatures and resist rutting. Additionally, the inclusion of plant oils in petroleum-based asphalt can reduce the polymer content by adding light components. WVO, in particular, significantly alters the composition of the asphalt’s colloidal system, resulting in notable changes to its high-temperature performance compared to conventional asphalt.

To address the trade-off between high- and low-temperature performance in plant oil-modified bitumen, some studies have looked at combining plant oil with other polymers or additives. For instance, research on composite bitumen modified with bio-oil and rock bitumen found that adding bio-oil improves low-temperature performance but decreases high-temperature resistance. The modification process is primarily physical, and except for waste and plant oils, there is no clear relationship between the rheological properties of other bio-oils and their infrared spectra.

In another study, PET particles treated with WVO were mixed into bitumen and aged in the lab using RTFO and PAV methods. The changes in the bitumen’s properties were tracked using dynamic shear rheometer (DSR) and FTIR spectroscopy. The findings showed that oil-treated PET-modified bitumen retained 15.6% of its healing ability after long-term aging, while the untreated binder lost nearly 66% of its healing capacity. This suggests that the addition of WVO-treated PET can effectively reduce aging in asphalt binders.

Plant oils in composite bitumen modification not only supplement light components but can also activate other additives, enhancing their overall performance and compatibility with bitumen. For instance, waste polymers like PVC, LDPE, PS, and PE can absorb the light components in bitumen, forming a network structure that improves viscoelasticity and enhances high-temperature performance, though it may also make the bitumen more prone to cracking at low temperatures. The compatibility between plant oil-modified bitumen and other additives varies depending on the materials used. Although these initial studies show promise for using plant oil in bitumen modification, more research is needed to optimize the techniques and fully understand how plant oil interacts with other materials in bitumen.

3.3 WVO as an Antioxidant

In addition to its role as a rejuvenator and modifier, sunflower seed oil (SO) has shown potential as an antioxidant modifier in asphalt binders. It has been observed that the inclusion of SO can improve fatigue resistance and delay aging in asphalt binders. The α-tocopherol present in sunflower seed oil is believed to react with carboxylic acids and anhydrides in the binder, forming esters that slow down aging and inhibit the evaporation of light components in the binder. Similarly, ricinoleic acid, the main component of castor oil, contains hydroxyl groups that may also react with the same compounds in asphalt, though further research is needed to clarify its anti-aging effects.

Similarly, ricinoleic acid, the main component of castor oil, contains hydroxyl groups that may also react with the same compounds in asphalt, though further research is needed to clarify its anti-aging effects.

4 Manure-Based Bio-Bitumen

Bio-bitumen, derived from organic materials like manure, offers several economic, social, and environmental advantages. Its use helps reduce the reliance on non-renewable resources and contributes to environmental sustainability. Modifying bitumen with materials such as swine manure aligns with these goals.

4.1 Production of Swine Manure Bio-Oil

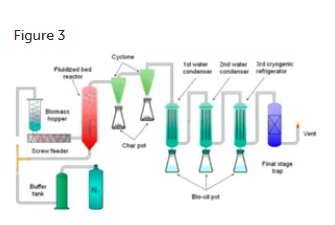

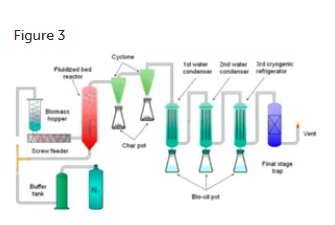

Researchers have developed methods to produce bio-oil from swine manure. One such method involves dehydrating and crushing manure particles before passing them through a fluidized bed reactor under nitrogen flow. Inside the reactor, the manure particles quickly exchange heat with preheated quartz stones in an oxygen-free environment, undergoing rapid pyrolysis as the temperature rises quickly.

4.2 Impact of Manure-Based Bio-Oil as a Bitumen Modifier

Following the development of this modifier, assessing its effectiveness is crucial, particularly through basic performance tests for bitumen and asphalt mixtures.

A study evaluated the behavior of modified bitumen produced by various methods under high and low temperatures using MSCR and BBR testing. The findings revealed that adding bio-oil from swine manure to petroleum bitumen improves workability but negatively affects its performance at high temperatures and its resistance to fatigue.

Despite the negative impact on bitumen’s high-temperature characteristics, the manure-derived bio-oil enhances bitumen’s flexibility. In another evaluation, the performance and workability of bitumen with and without a bio-binder made from swine manure and Recycled Asphalt Shingles (RAS) were compared. The results demonstrated a significant improvement in ductility and fracture energy in the RAS-modified bitumen when the bio-binder was added.

Moreover, research involving the addition of a swine-manure-based biological modifier to Reclaimed Asphalt Pavement (RAP) material showed that this bio-modified binder improved fatigue resistance and crack durability without compromising moisture sensitivity or rutting resistance.

Another study utilized various methods, including DSR and X-ray diffraction, to analyze the chemical makeup and structure of biochar and bio-oil derived from waste wood and swine manure. This research indicated that biochar can significantly change the fundamental properties of petroleum bitumen, such as softening point, viscosity, and complex modulus. Importantly, the performance of upgraded manure-based bio-oil surpasses that of untreated bio-oil, increasing its potential for replacing petroleum asphalt partially or entirely.

4.3 Influence of Manure-Based Bio-Oil on Bitumen’s Antioxidation and Rejuvenation

It has been observed that bio-oil from swine manure shows effective resistance to bitumen aging and contributes to its rejuvenation, which could be key to its application as a swine manure modifier. One study explored the effects of introducing bio-binders made from swine manure, mango grass, corn straw, and sawdust on the chemical and rheological properties of bitumen before and after aging. Results indicated that swine manure-based bio-binders are less prone to aging compared to plant-derived bio-oils.

Another research introduced a bio-binder made from swine manure through hydrothermal liquefaction, which was used to modify silica nanoparticles. These bio-binder functionalized nanoparticles were characterized through various techniques and demonstrated superior capability in slowing the aging of bitumen, while being cost-effective.

Further analysis examined aged bitumen before and after rejuvenation, showing that the bio-oil derived from swine manure significantly restored its performance. Additionally, research on co-liquefying high-protein algae with swine manure resulted in bio-oils that could restore the molecular balance of aged bitumen, enabling its rejuvenation.

In conclusion, swine manure-modified bitumen is often combined with other modifiers in the rejuvenation of aged bitumen. Its addition enhances bitumen’s flexibility and low-temperature performance, though an incorrect dosage can negatively impact high-temperature performance and fatigue resistance.

5 Conclusion

This article provides a comprehensive overview of the latest advancements in the use of bio-binders for asphalt pavements. The potential and challenges associated with bio-based additives have been discussed. Specifically, wood-based bio-oils, waste cooking oils, and manure-based bio-oils were identified as some of the most promising alternatives for modifying or replacing petroleum bitumen.

Several conclusions can be drawn from this review:

1.Currently, bio-based oils are primarily suitable as additives, such as softeners, rejuvenators, or modifiers, rather than being complete replacements for binders. Studies have shown that bio-oils can work effectively as additives; however, existing technologies do not yet support replacing petroleum-based bitumen with bio-oils.

2.Among the most promising uses for bio-oils is their role as rejuvenators. Research indicates that bio-oils can soften aged bitumen, reducing its stiffness and enhancing flexibility. This improvement boosts bitumen’s low-temperature performance and resistance to fatigue while maintaining adequate high-temperature performance.

3.Bio-oils also hold potential as antioxidants. Research clearly demonstrates that bitumen modified with bio-oils shows greater resistance to aging, suggesting that bio-oils could serve a dual function in bitumen modification.

4.Bio-oil and polymer blends offer another approach to enhancing bitumen performance across a wide temperature range, particularly for rejuvenating aged binders. The inclusion of polymers can help address high-temperature performance concerns. However, compatibility among the different components remains a primary challenge.

BY WPB