Tian Liang a,b,*, Jian-Feng Wang a,b, Xuan Kou c,d, Ping’an Peng a,b

a State Key Laboratory of Organic Geochemistry, Guangzhou Institute of Geochemistry, Guangzhou 510640, China

b CAS Center for Excellence in Deep Earth Science, Guangzhou 510640, China

c CAS Key Laboratory of Gas Hydrate, Guangzhou Institute of Energy Conversion, Chinese Academy of Sciences, Guangzhou 510640, China

d Guangdong Provincial Key Laboratory of New and Renewable Energy Research and Development, Guangzhou 510640, China

A B S T R A C T

Natural bitumen is an important component with high-purity organic matter in fossil energy and energy engineering scenarios. However, the production and application of natural bitumen could be severely hindered by the lacking of understanding the effects and influencing mechanisms of original components on physical properties of natural bitumen. Therefore, the main purpose of this work is to illustrate the influence mechanisms of original components (saturated hydrocarbon, aromatic hydrocarbon, resin and asphaltene) on mechanical properties of natural bitumen by the combination of nanoindentation technology and molecular structure analysis. The effects of each original component on the mechanical properties were carried out for Wuerhe natural bitumen which collected from Junggar Basin of China, and the influencing mechanisms were further revealed based on nanoindentation and X-ray diffraction (XRD) results. The occurrence units of each component in the chemical structural stacking of bitumen were established for the first time. It was found that hydrocarbons and resins can disintegrate the chemical structural stacking, thereby reducing the mechanical strength of natural bitumen.

According to our micro-scale analysis results, the plastic and elastic deformation of natural bitumen were controlled by the structural units of amorphous carbon and aromatic carbon microcrystalline, as determined by

saturated and aromatic hydrocarbons, respectively. And the schematic diagram of occurrence of each component in solid bitumen for the first time. Hence, the mechanical strength of natural bitumen can be effectively reduced by retaining or increasing the content of alkanes during exploitation, transportation and processing of natural bitumen. This research provided a new understanding for the stacking structure and physical property change mechanism of natural bitumen.

Keywords:

Natural bitumen,Nanoindentation,Mechanical properties,Microcrystal,Transformation

1. Introduction

Natural bitumen, also known as nature asphalt in many researches, is a kind of natural high-purity organic matter formed through the oxidation process after the light components (e.g. hydrocarbon) volatilized

from the petroleum [1–3]. Therefore, it mostly exists in source and reservoir rocks, especially in many petroliferous sedimentary basins [2,4–7]. Natural bitumen has been widely found and mined as an energy

mineral, and there are more than 360 billion barrels of proven natural bitumen reserves around the world, including Canada (Alberta), the United States (Utah, California, Texas), Russia (Volga River region, Siberia) [8–11]. Natural bitumen is produced as black massive, layered or banded solid under the geological environment (different from viscous liquid heavy oil), with vitreous luster and conchoidal fracture. According to Jacob (1989), the relative proportion of organic carbon in natural bitumen ranges from 72 to 93 %, and the chemical skeleton is composed of hydrocarbon structure, contained a small amount of nitrogen, oxygen and sulfur hetero-atoms [12,13]. Like petroleum, natural bitumen can be partially dissolved by liquid organic solvents, and it can

be divided into four organic components: Saturated hydrocarbon, Aromatic hydrocarbon, Resin and Asphaltene by column chromatography (SARA) [3,6,14–16]. Due to the high purity of organic matter and long-term evolution, natural bitumen has the characteristics of cohesiveness, waterproofness, corrosion resistance and non-toxic, and the natural bitumen has received extensive attention in many research fields. As an energy source, solid bitumen is used to evaluate the source and total resource of oil and natural gas [17–19]. Based on the pyrolysis experiment of natural bitumen, Wang et al. [19] suggested that the generation age of natural

gas from bitumen in Sichuan Basin of China was about Early Jurassic- Early Cretaceous. As an organic mineral, it is widely used in urban construction such as pavement [20–22]. Wititanapanit [23] carried out experiments on the modification of bitumen with natural rubber and suggested that natural rubber-modified bitumen with a concentration of up to 7 % by weight of bitumen is more suitable for paving roads in tropical regions. Wang et al. [24] carried out the research on the modification of natural bitumen and minerals, and proposed that the shear strength, freeze–thaw splitting strength ratio and fatigue life of asphalt based on natural modified materials were higher than those of base asphalt and styrene–butadiene–styrene control mixture. Duan et al. [25] compared the zinc oxide/expanded vermiculite (ZnO/EVMT) composite modified bitumen with the method of X-ray diffractometer (XRD), field emission scanning microscopy (FESEM) and Fourier transform infrared spectrometer (FTIR), and considered that HP-ZnO/EVMT had better aging resistance than SG-ZnO/EVMT [25]. It is worth noting that in the past decade, researchers have gradually pay attention to the impact of components of petroleum and bitumen of natural bitumen properties [26–30]. Zhang used C9 petroleum resin to modify natural asphalt, and found that C9 petroleum resin can effectively improve the fracture density, viscosity and anti-ageing performance of natural bitumen [29]. It was found that the addition of 15 wt% coal tar pitch to petroleum bitumen could decrease the elastic deformation of bitumen and improve the anti-aging effect [28].

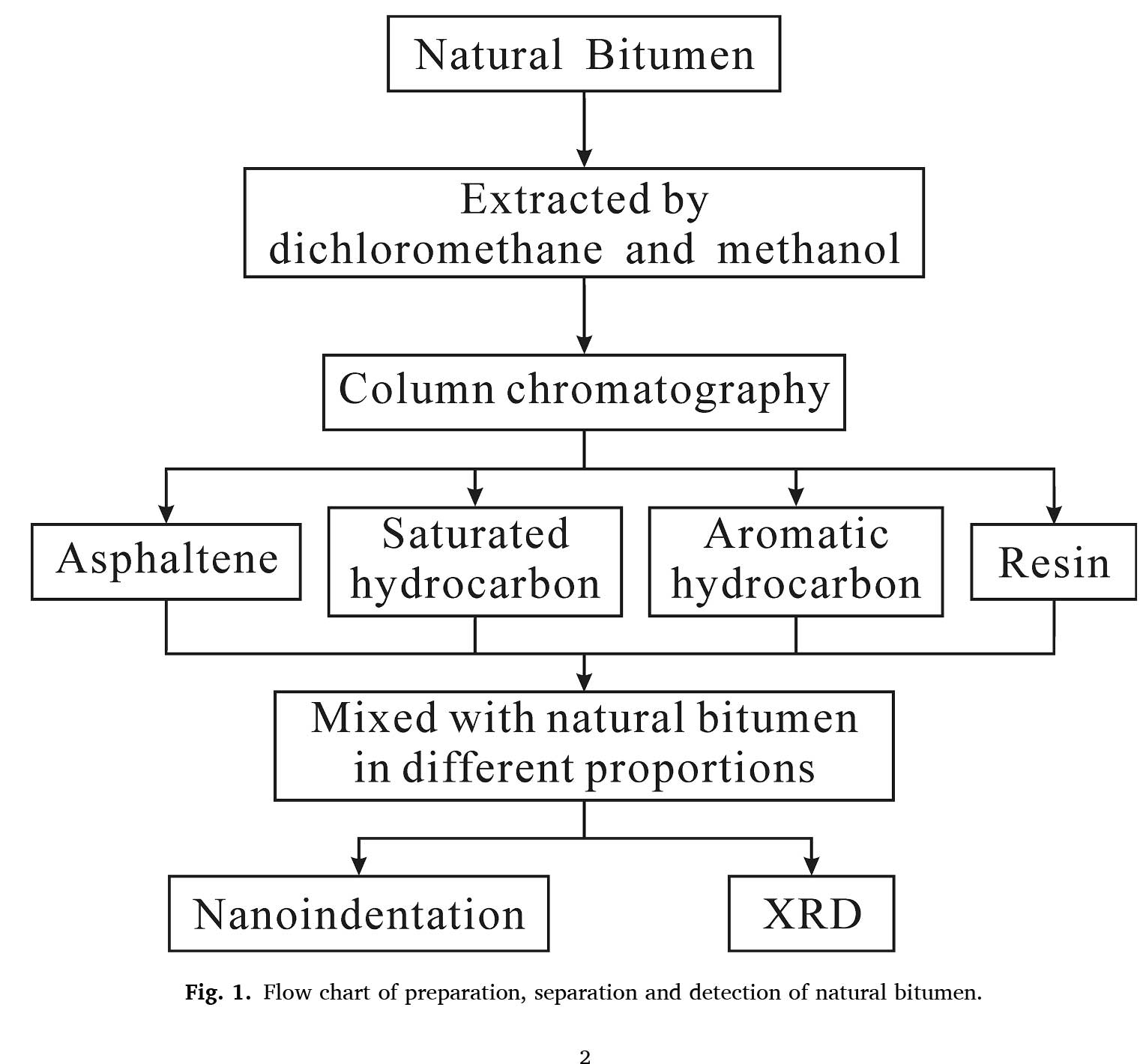

With the development of the research of modified bitumen, the properties of natural bitumen have gradually become the focus of researchers [11,20,22]. Song et al. [31] carried out the research of property of natural bitumen with different maturity based on raman spectroscopy and micro-FTIR. Farhan et al. [32] explored the chemical structure characteristics of natural bitumen in western Iraq. However, there are still two research gaps as we known: (1) What is the effect of different components (SARA) on the physical properties such as hardness and elasticity of natural bitumen? (2) How do the SARA reform the chemical structure of natural bitumen, and what is the interaction mechanism in this process? They are not just two scientific problems, the answers of them could directly solve a series of application energy problems in the process of mining, transportation, processing of natural bitumen and the exploitation and refining of petroleum. In this study, the natural bitumen with low maturity was selected as the object. After the four components (SARA) were obtained by column chromatography, they were mixed with the original natural bitumen according to a certain proportion with different weight ratios, respectively. X-ray diffraction (XRD) was used to analyze the occurrence space of each component in the natural bitumen and the transformation of the chemical structure; the method of nanoindentation was carried out to detect variations in Young’s modulus and hardness of samples. Explored the influence of each component on the properties of natural bitumen, revealed the mechanism of this process, and provided the theoretical support for the application of natural bitumen.

2. Material and method

2.1. Materials

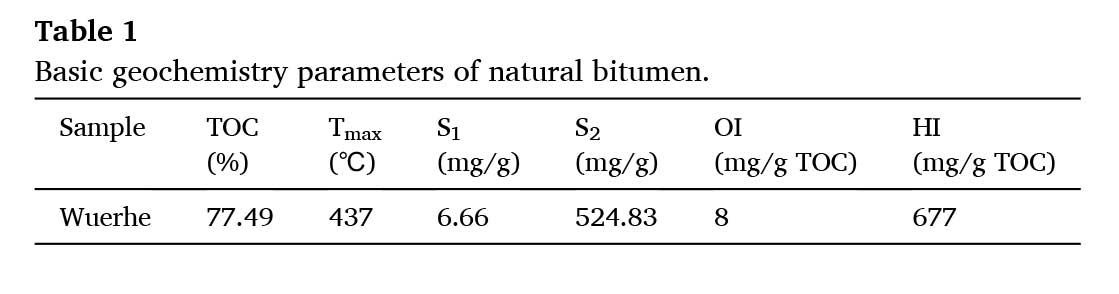

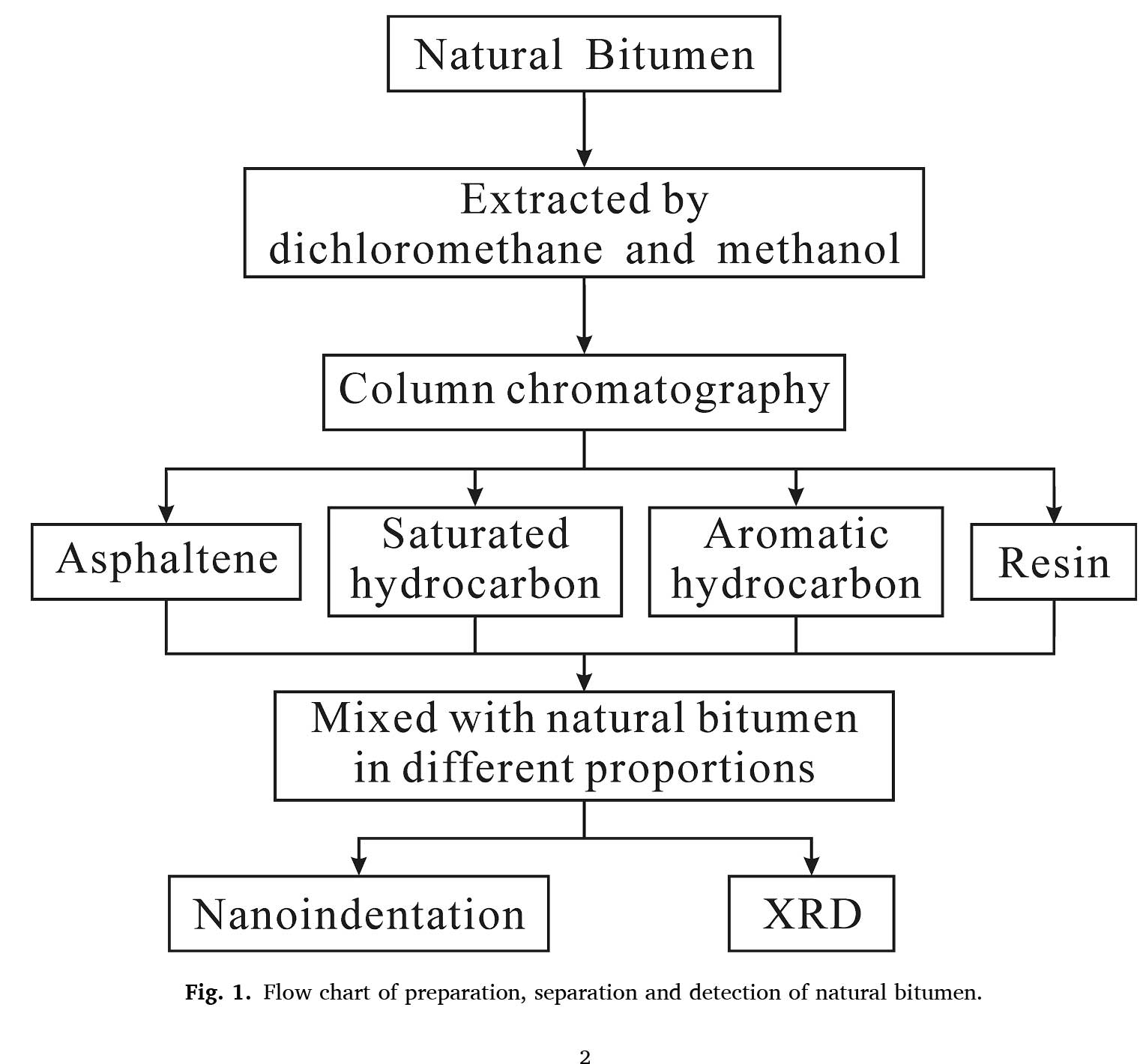

The natural bitumen used in this research is the Wuerhe natural bitumen collected from the city of Karamay, Junggar Basin, Xinjiang Province, Northwest of China. According to previous research, Wuerhe natural bitumen has high purity of organic matter, and it can be completely dissolved by organic solvent [33]. And the basic geochemistry parameters of Wuerhe natural bitumen have been listed in Table 1. The TOC (total organic carbon) of natural bitumen was 77.49 % and the HI (hydrogen index) was 677 mg/g TOC, which indicated that the organic matter purity of the sample is extremely high. The flow diagram of this study is shown in Fig. 1. The natural bitumen was ground to 120 mesh and extracted with a mixed reagent of dichloromethane and methanol (V:V 93:7) at the temperature of 50 ℃, to remove the ash and purify the bitumen. It should be noted that because natural bitumen contains the saturated hydrocarbons and aromatic hydrocarbons, high temperature will lead to the volatilization of some hydrocarbon compounds. Therefore, in this study, all of the experimental temperatures were controlled below 50 ℃ to eliminate the errors caused by the volatilize of compounds.

2.2. Sample preparation

Precipitated asphaltenes. The natural bitumen powder was placed in an 8 ml cell bottle. The n-pentane was added into the bottle and sonicated for 15 min to ensure adequate dissolution of the sample in the reagent. Then, the bottle was centrifuged for 15 min at a rate of 5000 r/ min to separate the insoluble material. After centrifugation, the supernatant was separated, and the insoluble solids at the bottom of the bottle

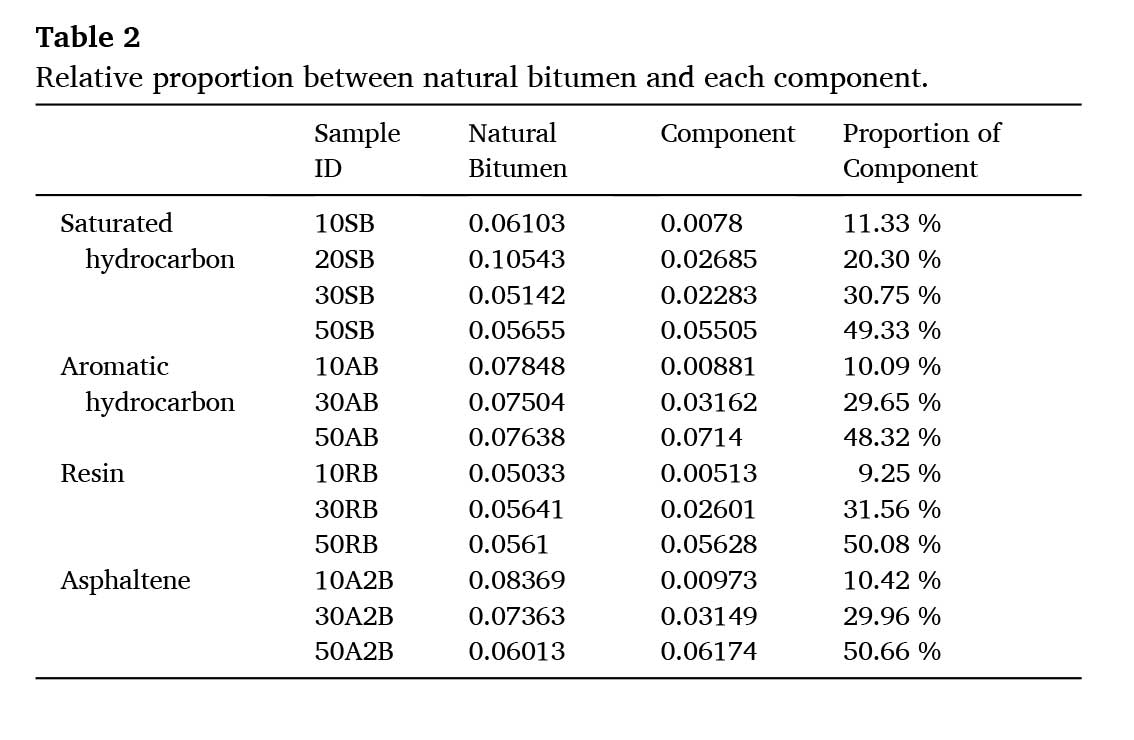

were asphaltenes in the natural bitumen. Column chromatography. The dissolved substances in the supernatant were separated by column chromatography. In this study, the column packing was alumina powder with a length of 15 cm. The sample was placed on the top of the chromatographic column. Then, the column is washed with n-hexane, n-hexane-dichloromethane mixed reagent (V: V 1:1) and dichloromethane-methanol mixed reagent (V:V 2:1) in turn, and the amount of the washing is 1.5 times of the volume of the chromatographic column. Finally, recovering the effluent flushing solvent, and volatilizing the reagent to obtain the components of saturated hydrocarbon, the aromatic hydrocarbon and the resin, respectively. Preparation of bitumen. As mentioned above, in order to ensure the stability of the light compounds during the experiment, reagents were used to dissolve and mix the natural asphalt and SARA. The certain amount of natural bitumen powder and the SARA are fully dissolved by dichloromethane-methanol reagent (V:V 93:7) respectively. Then, the solutions were mixed, stirred and volatilized in the oven at 30 ℃. The residual solid is a uniform mixture of the natural bitumen and SARA. The sample number and weight proportions are shown in Table 2. The weight fractions of SARA in the mixture were approximately 10 %, 30 %, and 50 %, respectively, and the point with 20 % saturated hydrocarbon was added.

2.3. Analysis

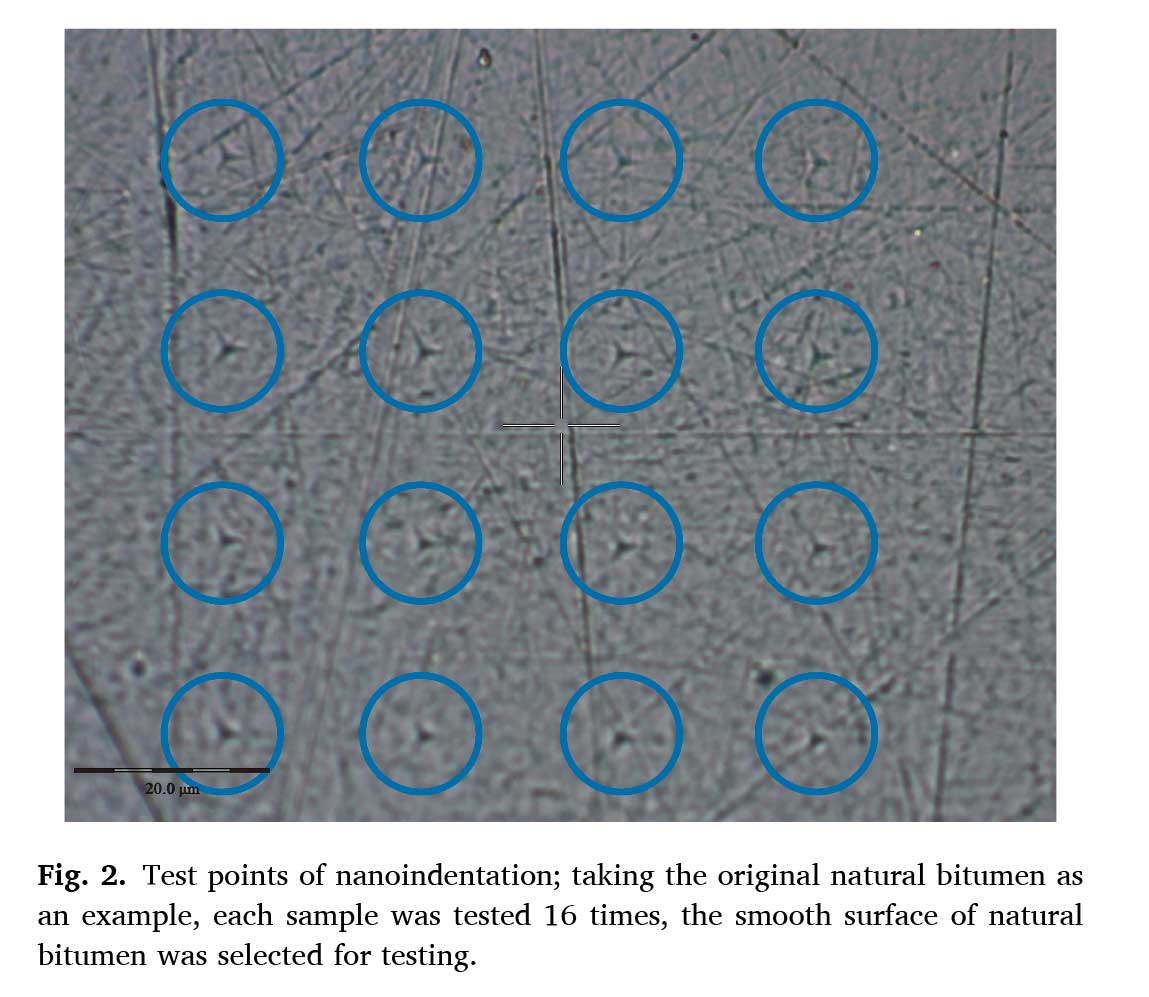

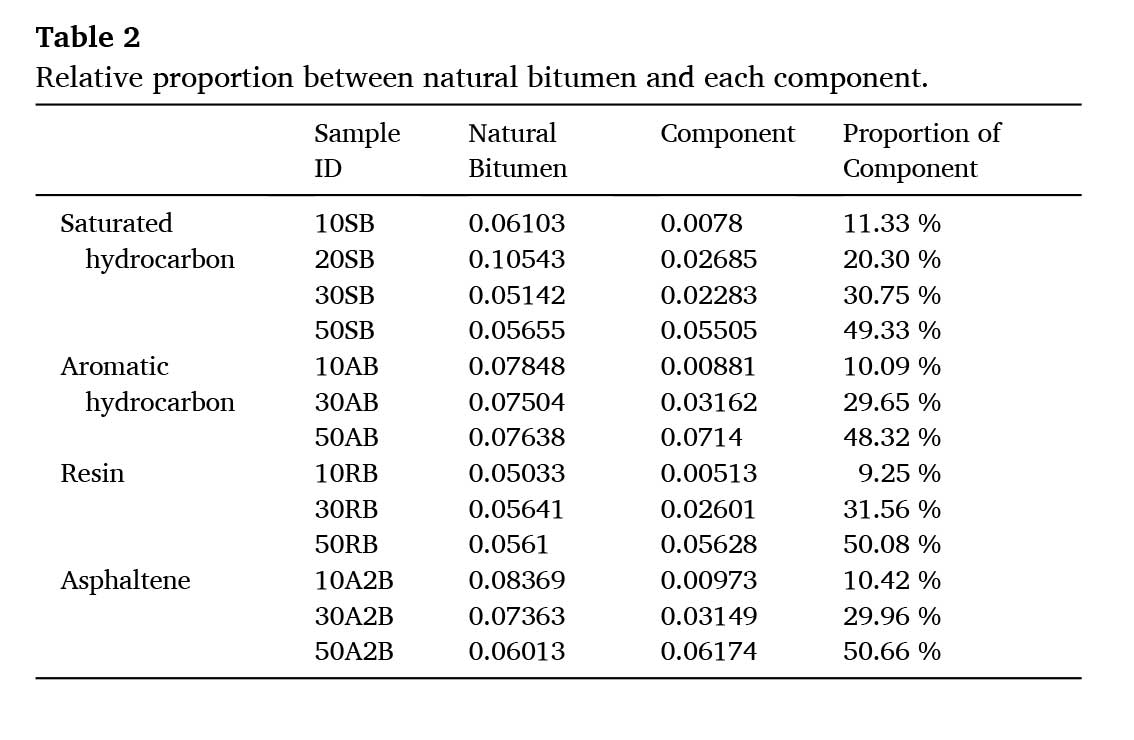

The nanoindentation were conducted on an Anton Paar TTX NHT3 nanoindenter to detect the properties of natural bitumen like Young’s modulus and hardness. The instrument equipped the diamond Berkovich indenter that has a three-sided pyramidal diamond tip with a radius of curvature of 50–100 nm. The stiffness threshold was 500 N/m and the spring compliance was 0.571 mm/N. The optical microscope of the

equipment with a maximum magnification of 4000× . Each sample was

tested 16 times (Fig. 2). The principle of the instrument and the details of

the parameter calculation method are described in our previous study

[34].

XRD was used to detect the information of structural stacking of

natural bitumen. As a new method to evaluate the structural characteristics

with different organic compositions, the feasibility has been

fully demonstrated in the field of energy research [3,35]. XRD-6100 XRay

Diffractometer with a Cu tube target at 40.0 kV and 30.0 mA was

used to continuous scan the samples, and the scan range was 10-80◦, the

speed was 2.0 deg./min.

3. Result and discussion

3.1. Results of nanoindentation

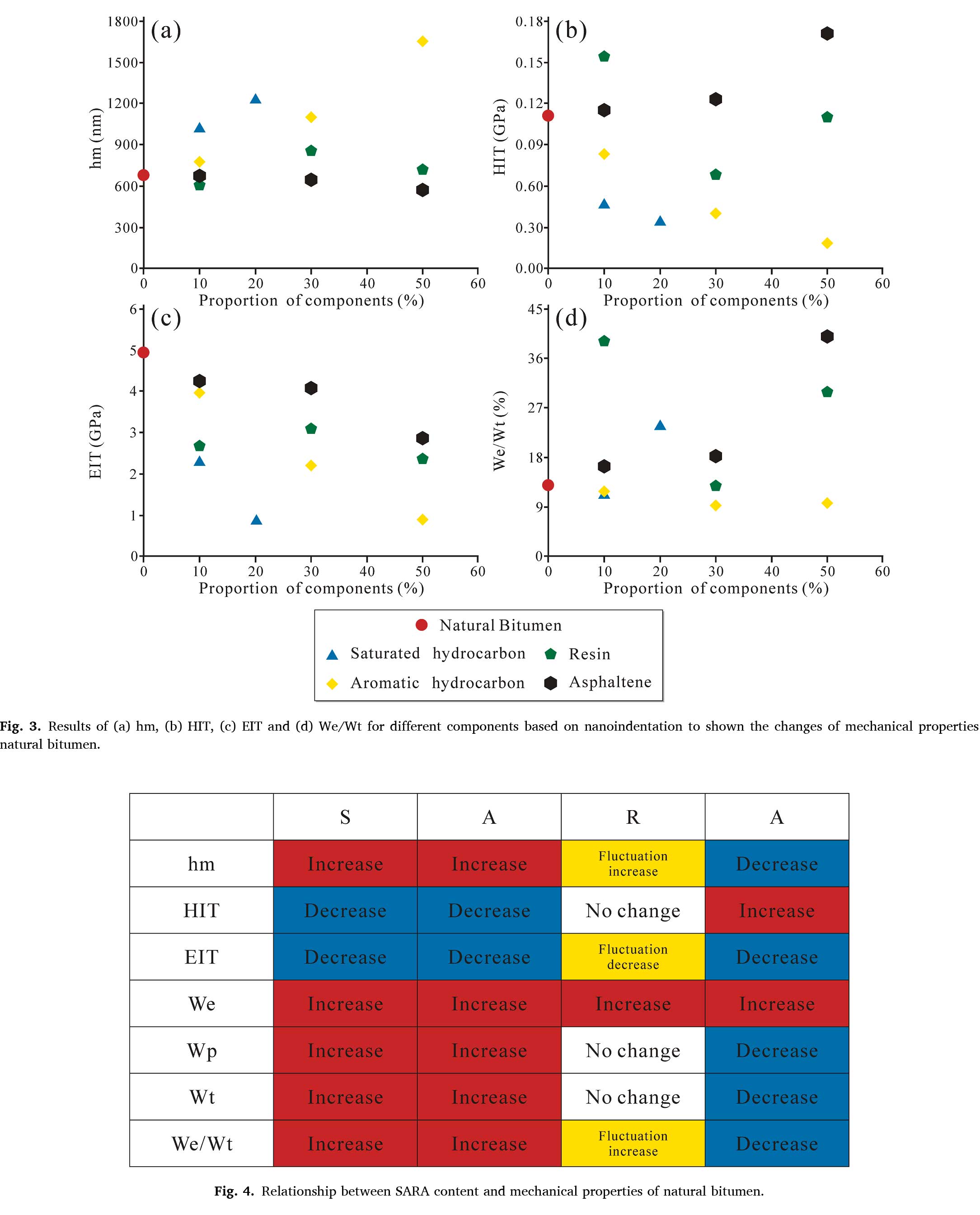

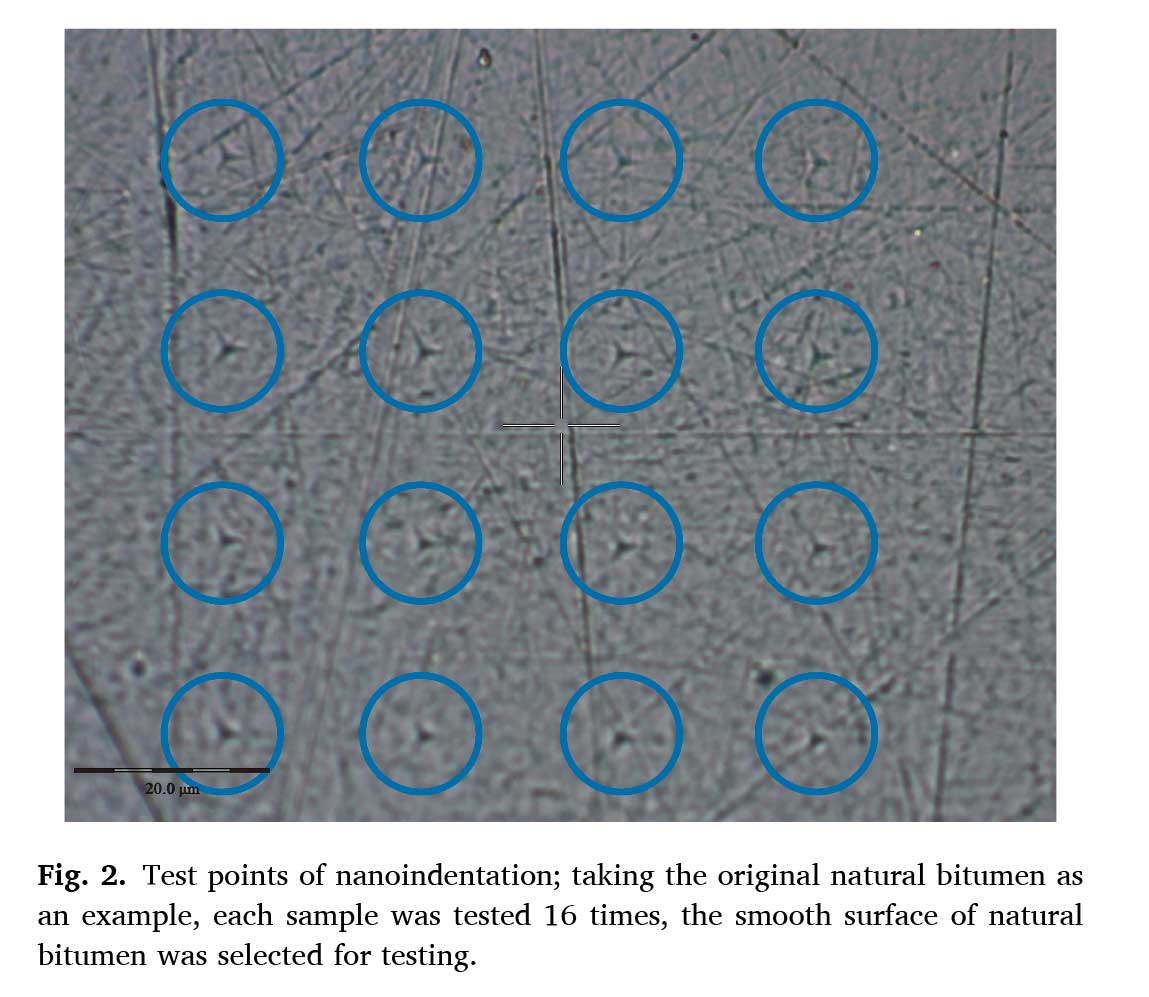

The results of nanoindentation experiments were shown in Fig. 3.

Nanoindentation completed the analysis of aromatics, resins and asphaltenes, but the mixture with 30 % and 50 % saturated hydrocarbon was too soft to complete the detection, so the samples with 20 % saturated hydrocarbon were supplemented. In Fig. 3 a, the changes of maximum indentation depth (hm) shown a significant difference in four components. hm represented the degree of samples affected by the scratching of the probe and the value of it is inversely proportional to the hardness of natural bitumen. With the increase of saturated hydrocarbons, the hm of natural bitumen rised from 676.00 nm to 1237.66 nm (20 wt%). With the proportion of aromatics increased from 0 to 50 wt%, the hm of natural bitumen increased from 676.00 nm to 1653.32 nm. During the same process, accompanied by an increase in the relative content of resin from 0 to 50 wt%, the hm fluctuate between 676.00 nm and 719.67 nm. Different from the former three components, the

asphaltene could reduce the hm of natural bitumen, and it decreased from 676.00 nm to 569.52 nm with the increase of the content of asphaltene from 0 to 50 wt%. The variation of the hardness (HIT) was shown in Fig. 3 b. The increase of saturated and aromatic hydrocarbons leaded to the hardness decrease of the sample from 0.11 GPA to 0.04 and 0.02 GPA,respectively. While, asphaltenes effectively increased the hardness of the natural bitumen from 0.11 GPA to 0.17 GPA (50 wt%). However, the effect of resin on the hardness was not obvious. The changes of Young’s modulus, variation of elasticity (EIT), were shown in Fig. 3 c. With the increase of the relative contents of saturates, aromatics and asphaltenes, the Young’s modulus of the samples decreased from 4.94 GPA to 0.89 GPA, 0.90 GPA and 2.87 GPA, respectively. However, the increase of resin proportion made this parameter decreased with fluctuation.

We/Wt (the elastic part of indentation work) shown the relationship between the elastic and the plastic deformation (Fig. 3 d). Among the four components, the We/Wt of the saturated hydrocarbon group increased from 13.05 % to 23.94 % (20 wt%). In asphaltenes, We/Wt increased from 13.05 % to 39.94 % (50 wt%). This indicated that with the increase of these two components, the natural bitumen deformed plastically to elastically. However, We/Wt of samples decreased from 13. 05 % to 9. 73 % with the increase of aromatic hydrocarbons, which suggested that the natural bitumen changed from elastic deformation to plastic deformation during this process. Different from those three compounds, there was no linear correlation between the proportion of resin and the We/Wt. The value of We/Wt fluctuated with the increase of resin content. This meant that resin might has little effect on the deformation characteristics of natural bitumen.

3.2. Influence of SARA on mechanical properties

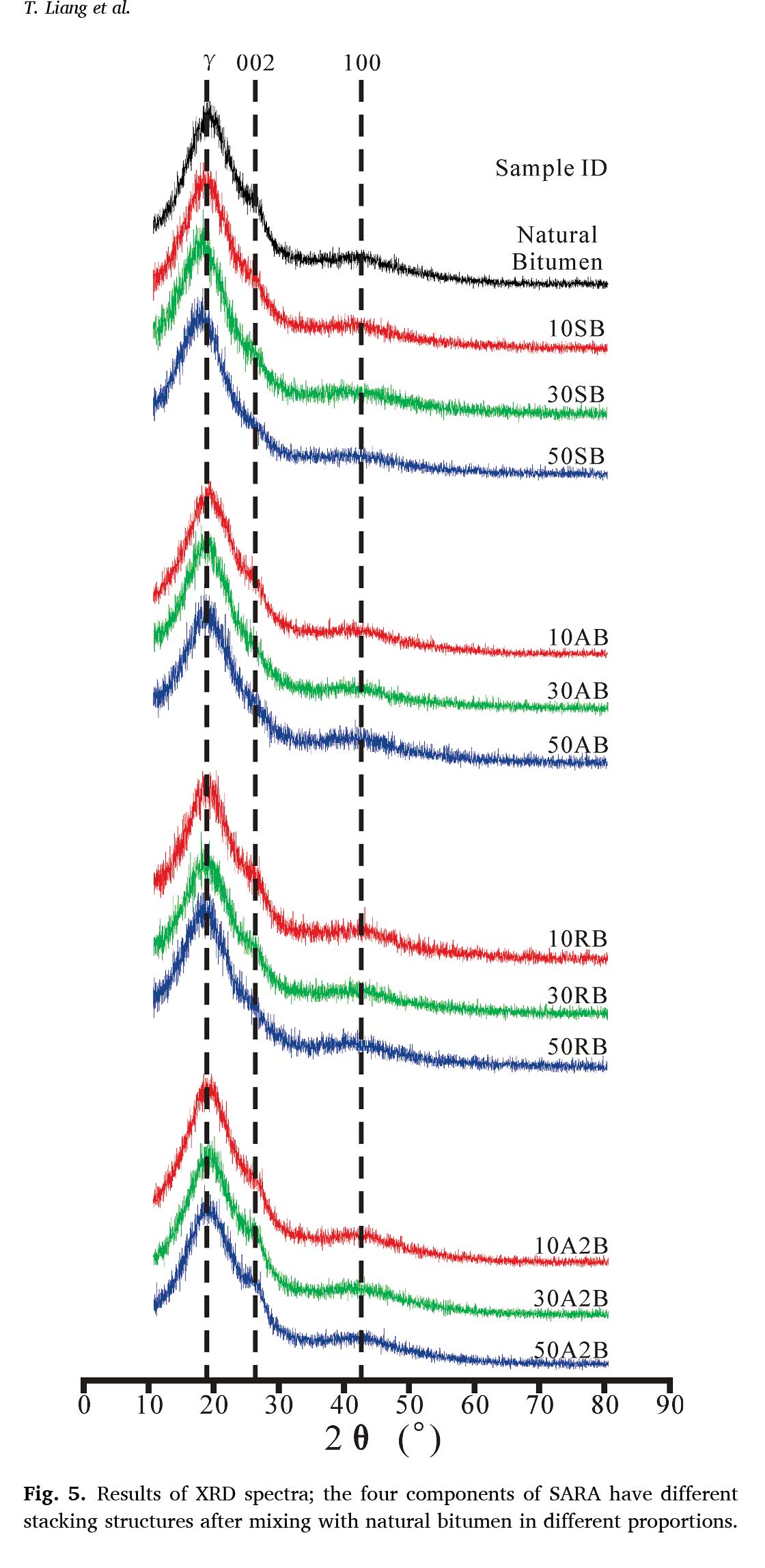

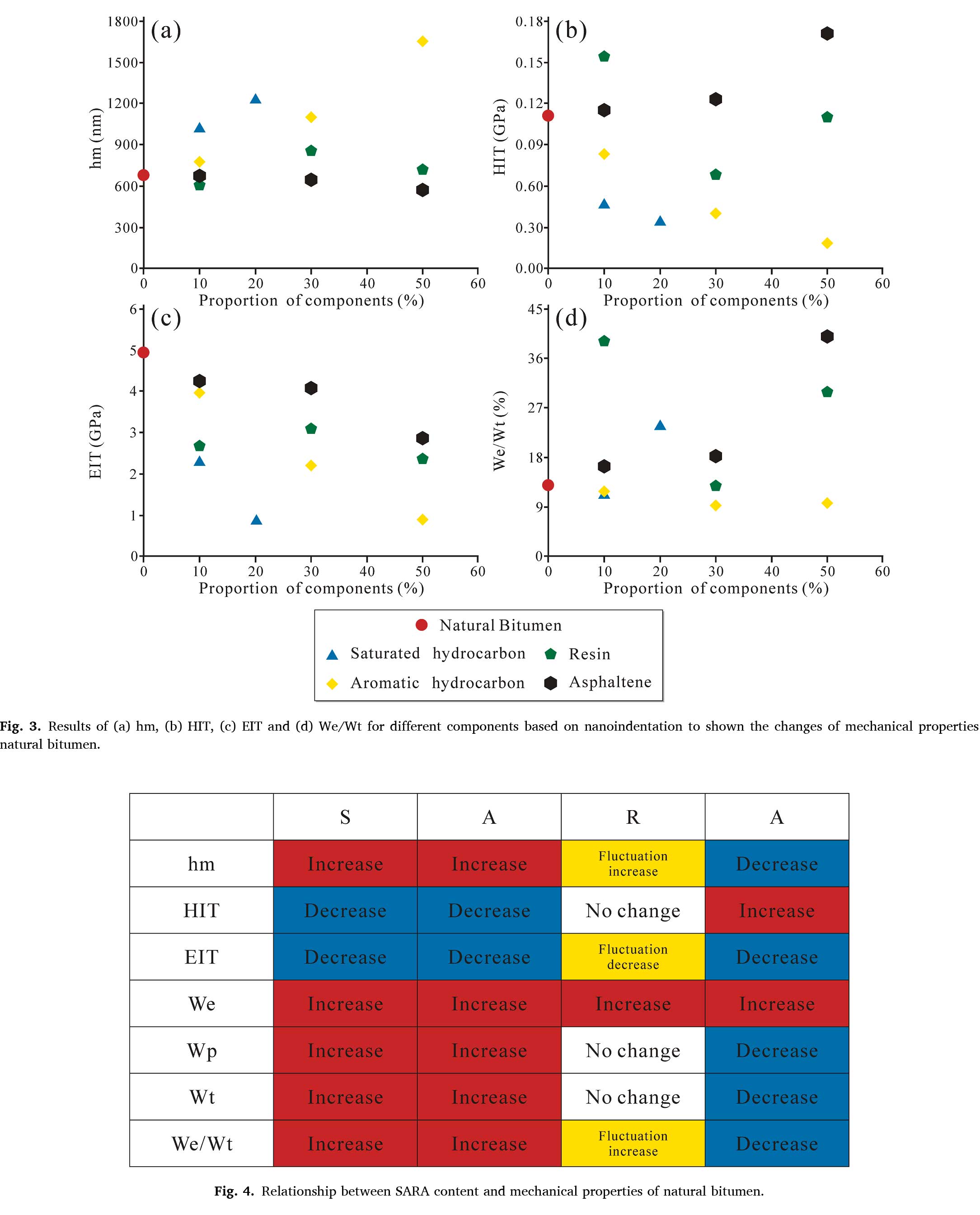

Based on the results of nanoindentation, the effects of SARA on the physical properties of natural bitumen are summarized as follows (Fig. 4):

(1) Hydrocarbon compounds can reduce the hardness and elasticity of natural bitumen, especially alkanes. Both saturated and aromatic hydrocarbons can effectively reduce the hm, HIT and EIT of samples. In addition, the HIT and EIT of the saturated hydrocarbon with 20 wt% were even equivalent to those of the aromatic hydrocarbon with 50 wt %, which indicated that the alkanes was the more effective. (2) Resin was the component which has the least influence on the properties of natural bitumen. The increase of resin content just has little effect on the changes of parameters. In Fig. 3, there is no clear correlation between the increase of resin content and four parameters, which may be due to the properties of resin are close to the natural bitumen, resulting in little change in the properties after mixing. (3) Asphaltene can enhance the hardness while reducing the elasticity of the natural bitumen. With the increase of asphaltene proportion,

the HIT iecreased, but the hm and EIT decreased. (4) The increase of aromatic hydrocarbon leaded to that the deformation of natural bitumen changed from elastic to plastic. The changes of We/Wt proved this phenomenon, and the influence of aromatic hydrocarbons on the deformation of natural bitumen was different from the other three components. The above phenomena leaded to the following two scientific problems: (1) Why was the effect of aromatic hydrocarbon on the deformation of natural bitumen different from the other three components? (2) How did SARA change the properties of natural bitumen? In the following study, we will try to solve these two problems by exploring the stacking of chemical structure of natural bitumen.

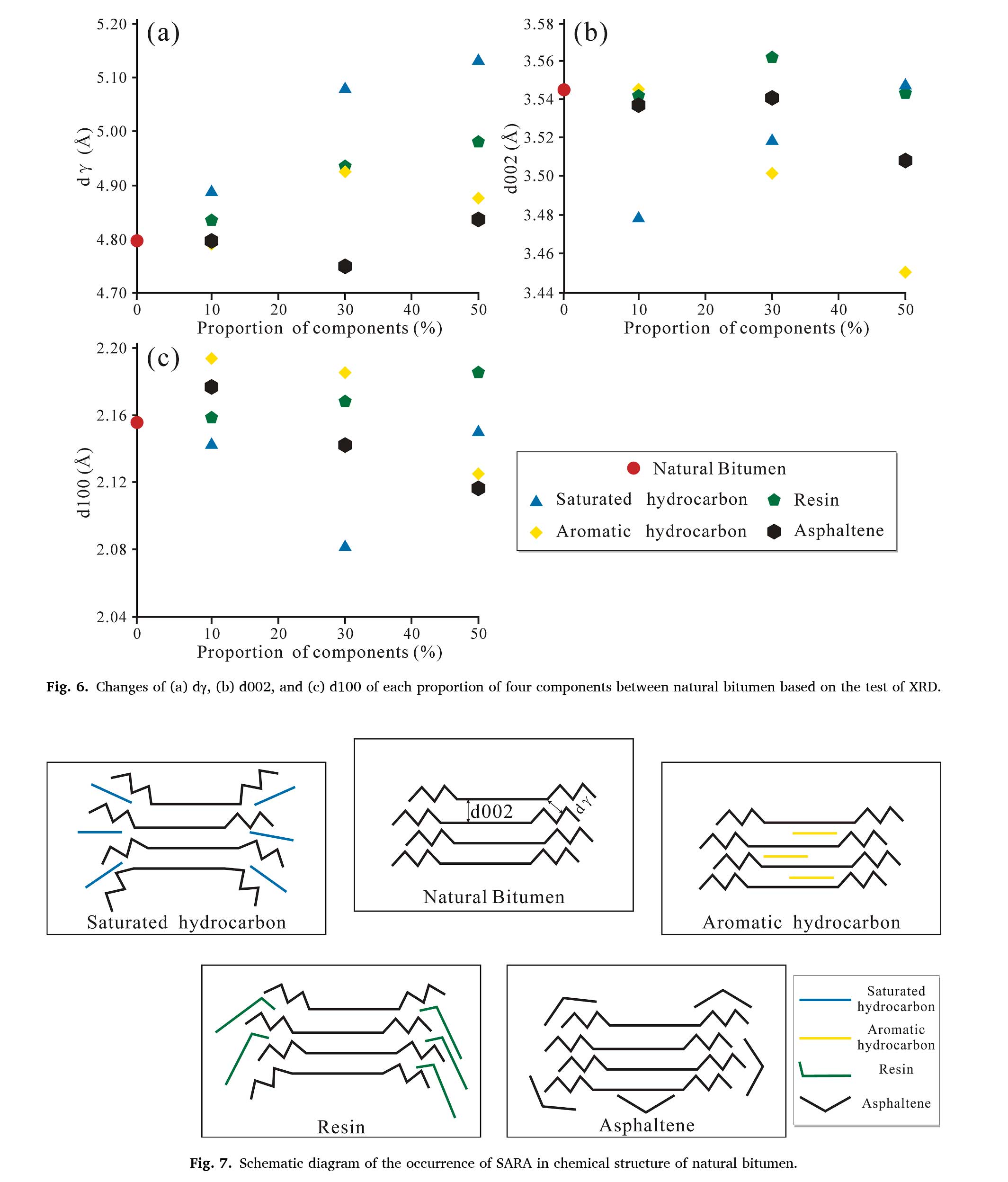

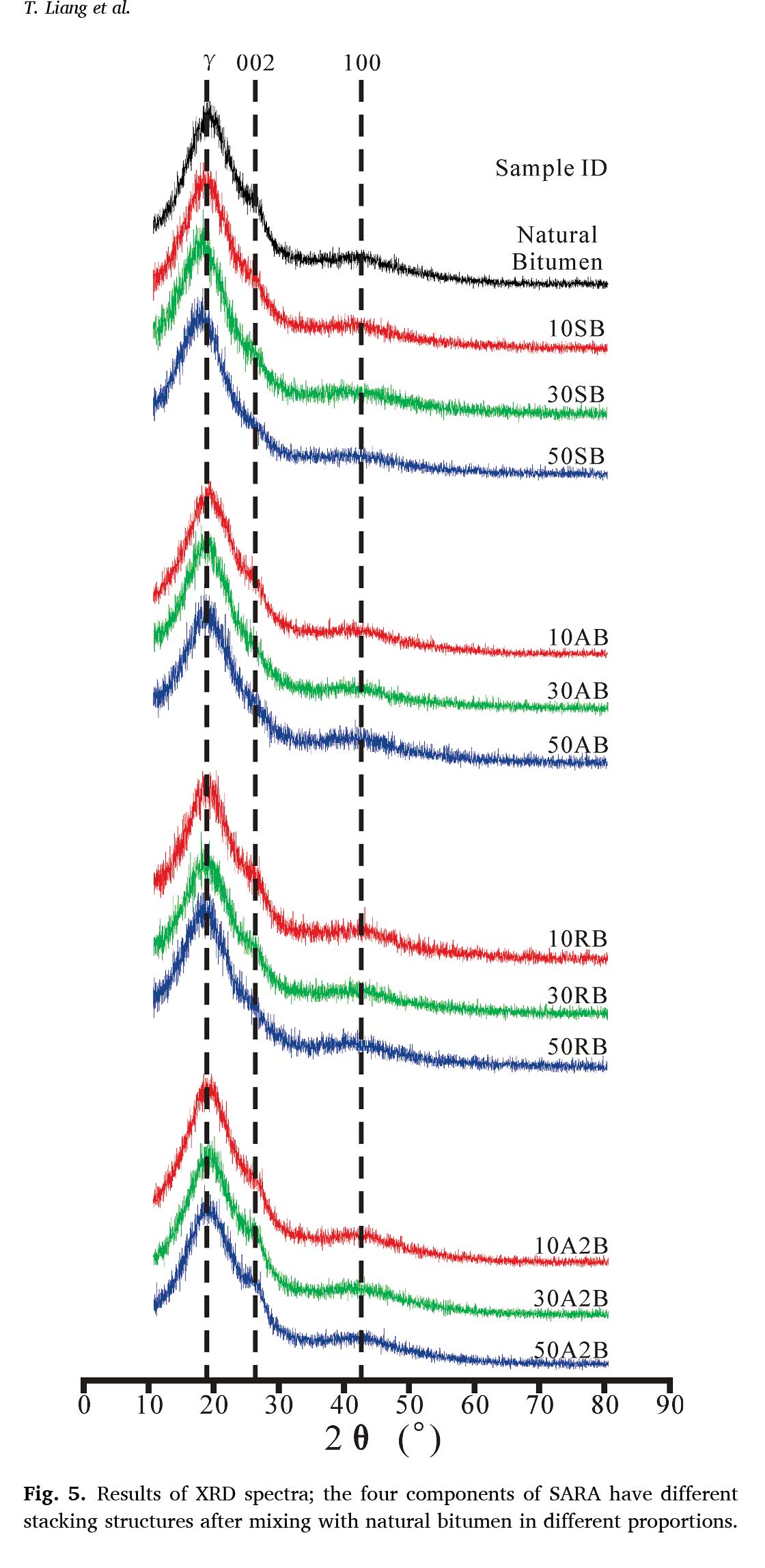

3.3. Changes in the natural bitumen chemical structure

The XRD results of the 13 samples are shown in Fig. 5. Each spectra shown the characteristics of graphite and without any mineral peaks, indicating that there was no mineral ash remained in natural bitumen samples [36]. There were three main peaks of organic matter could be identified from the spectra for the γ, 002 and 100 band, with diffraction angles of approximately 18◦, 26◦ and 47◦, respectively. The main peak of the 002 band represents the stacking of the aromatic rings and reflected the microcrystals of the polycondensed aromatic rings in the chemical structure of the samples [36,37]. There was a shoulder near 20◦ (diffraction angle) in the peak at 002, which was the γ-band and represented the aliphatic carbon functional groups, including aliphatic hydrocarbon chains, alicyclic hydrocarbons, and various aliphatic carbons connected in aromatic groups [38–40]. The band of 100 reflected the in-plane structure of the stacked aromatic

carbons, and it meant the first nearest neighbor functional groups of the aromatic clusters [41,42].

The peak position of the three structural units can be calculated according to Bragg and Scherrer formulas (Eqs. (1), (2), (3)) formula to

obtain the value of dγ, d002 and d100:

dγ = λ/(2sinθγ) (1)

d002 = λ/(2sinθ002) (2)

d100 = λ/(2sinθ100) (3)

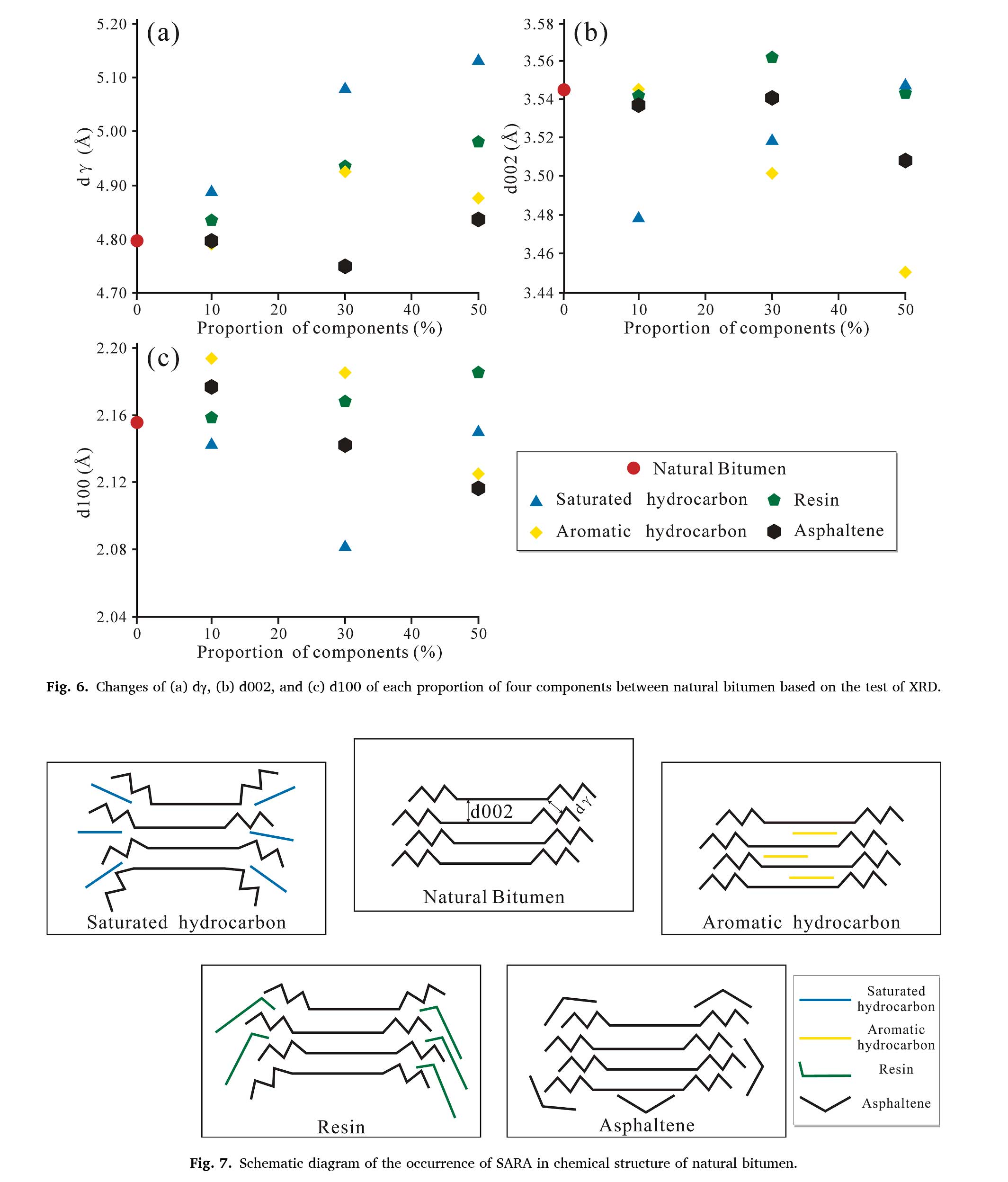

where dγ, d002 and d100 were the interlayer spacing of the amorphous carbons, microcrystals of aromatic carbons and the lateral adjacent unit of aromatic clusts, respectively; λ is the x-ray wavelength (0.15405 nm);

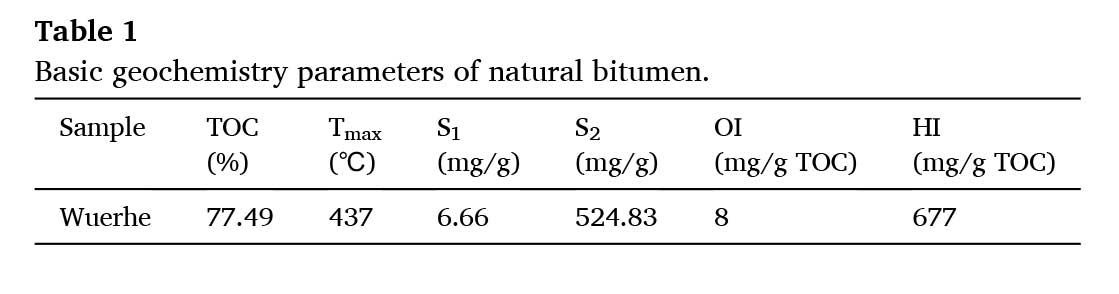

θγ, θ002, and θ100 represented the diffraction angles of γ, 002, and 100- peak positions [39]. As shown in Fig. 6, in the twelve sets, the dγ of saturated hydrocarbons and resins increased with their contents, from 4.80 Å to 5.13

and 4.9 Å, respectively. In addition, the rise of the relative proportion of resin resulted the d100 increased from 2.16 to 2.19 Å. This phenomenon indicated that saturated hydrocarbon mainly existed in the structural unit of amorphous carbon, and it has a stronger interaction with aliphatic compared with the aromatic carbons. During the process of interaction, saturated hydrocarbon molecules pried off part of the amorphous carbon components, resulting in the increase of the spacing (Fig. 7). This is consistent with the previous researches [3,35]. However, the resin was partly incorporated into the amorphous carbon unit and partly attached to the side of the organic microcrystal structure of the natural bitumen. The ability to modify the γ band was weaker than that saturated hydrocarbon (Fig. 7). With the increasing of the proportion of aromatic hydrocarbon from 0 to 50 wt%, the d002 decreased from 3. 54 to 3. 45 Å (Fig. 6). This phenomenon indicated that the aromatic compounds interacted with the aromatic carbon fraction of the bitumen. Small molecular compounds enter the interior of the aromatic cluster stack, resulting in the compression of the structure and the reduction of its spacing (Fig. 7).

The molecular structure of asphaltene was too large to enter the microcrystal structure, and it could not affect chemical stacking of the natural bitumen, and it is speculated that the asphaltene was only wrapped in the periphery of the microcrystal structure (Fig. 7).

In order to illustrate the influence of the four components on the chemical structure of natural bitumen accurately, Fig. 7 was drawn as a schematic diagram in this research.

3.4. Relationships between chemical structure and mechanical properties

From the perspective of microscopic, the four components change the chemical structure stacking, and from the macroscopic, they changed the mechanical properties of nature bitumen. (1) Saturated hydrocarbon was enriched in the γ band, resulting in the increase of amorphous carbon spacing. This phenomenon leaded to

the disintegration of the stack structure of natural bitumen, and the reduction of hardness and elasticity. In addition, free alkanes, which produced from the disintegration of the γ band, increased the proportion

of elastic work in the deformation process. (2) The aromatic hydrocarbon could lead to the disintegration of microcrystals, which reduces hardness and elasticity of natural bitumen. However, unlike saturated hydrocarbons and resins, aromatic hydrocarbons acted on the interior of microcrystals, resulting in the decrease of 002 band spacing. This phenomenon enhanced the plastic deformation of the 002 band, causing in the enhance of the plastic deformation. (3) Part of the resin structure combined with amorphous carbon,

leading to the reduction of hardness and the increase of elastic work. However, part of the resin structure existed on the side of the microcrystals, which weakened the impact of the reduction of hardness and

elasticity caused by the disintegration of γ band. Therefore, the increase of resin proportion has a little effect on the mechanical properties of natural bitumen. (4) Asphaltene was difficult to enter the microcrystals, and it was hard to cause the disintegration of chemical structure. At the same time, the hardness of natural bitumen increased since the asphaltene wrap around the outside of the microcrystals.

4. Conclusions

This study carried out research of the occurrence units of saturated hydrocarbon, aromatic hydrocarbon, resin and asphaltene (SARA) in chemical structure of natural bitumen for the first time, to provide theoretical support for identifying the effective mechanisms of SARA on the mechanical properties of bitumen. It is found that the elastic and plastic deformation behaviors of natural bitumen are determined by amorphous carbon and aromatic cluster microcrystals, as determined by saturated and aromatic hydrocarbons, respectively. This research proposed that the increase of hydrocarbons and resins will lead to the disintegration of the chemical structure of natural bitumen, while asphaltene molecules will enhance the structural strength of natural

bitumen. In the field of energy and urban applications, especially during the process of exploitation and transportation of natural bitumen, increasing the content of alkane properly can soften the bitumen and reduce its mechanical strength in an effective and efficient way. Additionally, for the applications of industrial field, rising the relative proportions of aromatic hydrocarbon and asphaltenes can effectively meet the requirements of high plasticity and strength. Hence, our findings towards the mechanical properties and transformation behaviors of natural bitumen under the effects of different original components can provide new insights and theoretical support for efficient exploitation and processing of natural bitumen minerals, as well as the transportation and refining of the petroleum, and many other energy and urban fields. CRediT authorship contribution statement Tian Liang: Writing – review & editing, Writing – original draft,

Funding acquisition, Data curation. Jian-Feng Wang: Writing – review & editing, Investigation. Xuan Kou: Funding acquisition. Ping’an Peng: Writing – review & editing. Declaration of competing interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Data availability All of data has been listed in manuscript.

Acknowledgment This work is supported by GuangDong Basic and Applied Basic Research Foundation (2023A1515011646). National Natural Science Foundation of China (52306286), China Postdoctoral Science Foundation (2022M723160). Thanks for Researcher Zou Yan-Rong and Xiong Yong-Qiang (Guangzhou Instituted of Geochemistry) provide the support of the experiment. Thanks to the editors and reviewers for their valuable comments on this article.

References

[1] Vandenbroucke M, Largeau C. Kerogen origin, evolution and structure. Org

Geochem 2007;38:719–833.

[2] Mastalerz M, Drobniak A, Stankiewicz AB. Origin, properties, and implications of

solid bitumen in source-rock reservoirs: a review. Int J Coal Geol 2018;195:14–36.

[3] Liang T, Zou YR, Zhan ZW, Peng P. Chemical structure changes of solid bitumen

during solvent swelling investigated by X-ray diffraction. Int J Coal Geol 2021;243:

103778.

[4] Chilingarian GV, Yen TF. Bitumens, Asphaltes and Tar Sands. Elsevier Amster

1978. p. 331.

[5] Moore LV. Significance, classification of asphaltic materials in petroleum

exploration. Oil Gas J 1984;82:109–12.

[6] Kelemen SR, Walters CC, Kwiatek PJ, Freund H, Afeworki M, Sanasone M, et al.

Characterization of solid bitumens originating from thermal chemical alteration

and thermochemical sulfate reduction. Geochim Cosmochim Acta 2010;74:

5305–32.

[7] Rippen D, Littke R, Brun B, Mahlstedt N. Organic geochemistry and petrography of

Lower Cretaceous Wealden black shales of the Lower Saxony Basin: The transition

from lacustrine oil shales to gas shales. Org Geochem 2013;63:18–36.

[8] Meyer RF, Attanasi ED. Heavy oil and natural bitumen strategic petroleum

resources: U.S. Geological Survey, 2003;Fact Sheet 70-3.

[9] Meyer RF, Freeman PA. Siberian platform: Geology and natural bitumen resources:

U.S. GeologicalSurvey, 2006;Open-File 2006-1314,p.24.

[10] Schamel S, Overland S, Ibatullin R. Bitumen heavy oil committee commodity

report. AAPG 2015:p.55.

[11] Hein FJ. Geology of bitumen and heavy oil: an overview. J Petrol Sci Eng 2017;

154:551–63.

[12] Jacob H, Wehner H. Mikroskopphotometrische analyse disperser festbitumina in

sedimenten. Deutsche Gesellschaft fur Mineralolwissenschafr und Kohlechemie

DGMK-Projekt 1981:p.257.

[13] Jacob H. Classification, structure, genesis and practical importance of natural solid

oil bitumen (“migrabitumen”). Int J Coal Geol 199;11:65–79.

[14] Wen CS, Chilingarian GV, Yen TF. Properties and structure of bitumen. In:

Developments in Petroleum Science. Elsevier; 1978. p.155-190.

[15] Hwang RJ, Teerman SC, Carlson RM. Geochemical comparison of reservoir solid

bitumens with diverse origins. Org Geochem 1998;29:1–3.

[16] Hosterman WT, Xu GY. Experimental study of high temperature properties and

rheological behavior of Iranian rock asphalt. In: Advanced Materials Research.

Trans Tech Publ 2013.

[17] Zhang Q, Huang HP, Zheng LJ, Qin JZ. Secondary hydrocarbon generation

potential from heavy oil, oil sand and solid bitumen during the artificial

maturation. Org Geochem 2007;3:2024–35.

[18] Xiong YQ, Jiang WM, Wang XT, Li Y, Chen Y, Zhang L, et al. Formation and

evolution of solid bitumen during oil cracking. Mar Petrol Geol 2016;78:70–5.

[19] Wang ZX, Wang YL, Wu BX, Wang G, Sun ZP, Xu L, et al. Hydrocarbon gas

generation from pyrolysis of extracts and residues of low maturity solid bitumens

from the Sichuan Basin. China Org Geochem 2017;103:51–62.