Oxidized Bitumen (Blown / Oxidized Bitumen) is a bitumen obtained from refining when hot air is blown into penetration-grade bitumen or straight-run bitumen. This raises the softening point, lowers penetration, and forms different physical properties such as improved adhesion, chemical resistance, and high-temperature stability.

Oxidized bitumen is occasionally simply referred to as Blown Bitumen or, in some industrial applications, Rubberized Bitumen. Within grading, the letter R is utilized to indicate that the blow process has been completed, and the figures which follow it (e.g., R SP/PEN or R90/40) denote the grade:

• R is the rubberized capability.

• The first figure is the Softening Point (°C).

• The second figure is the Penetration at 25°C.

For instance, R90/40 refers to a softening point of around 90°C and a penetration value of around 40.

Production Process of Blown Bitumen

Penetration-grade bitumen, refinery residue (vacuum residue) or cut-back is charged in a reactor. Heated air (usually by means of perforated pipes or nozzles) at a specific temperature is blown into it. It induces a polymerization reaction, reducing the hydrogen-to-carbon ratio and giving a material of higher softening point. The process temperature generally ranges from 200–300°C, and the temperature and the air flow rate need to be very precisely controlled in order to obtain different grades.

Physical and Mechanical Properties of Blown Bitumen

•Softening Point: Far higher than base penetration bitumen, which gives more resistance to softening at high temperatures.

•Penetration: Lower, thus giving a harder surface.

•Adhesion: Typically better, which is why it is suited for coatings and insulation applications.

•Chemical Stability & Water Resistance: Improved, which is one of the reasons it is commercially applied to sealing and pipelining protection.

Application of Oxidized Bitumen

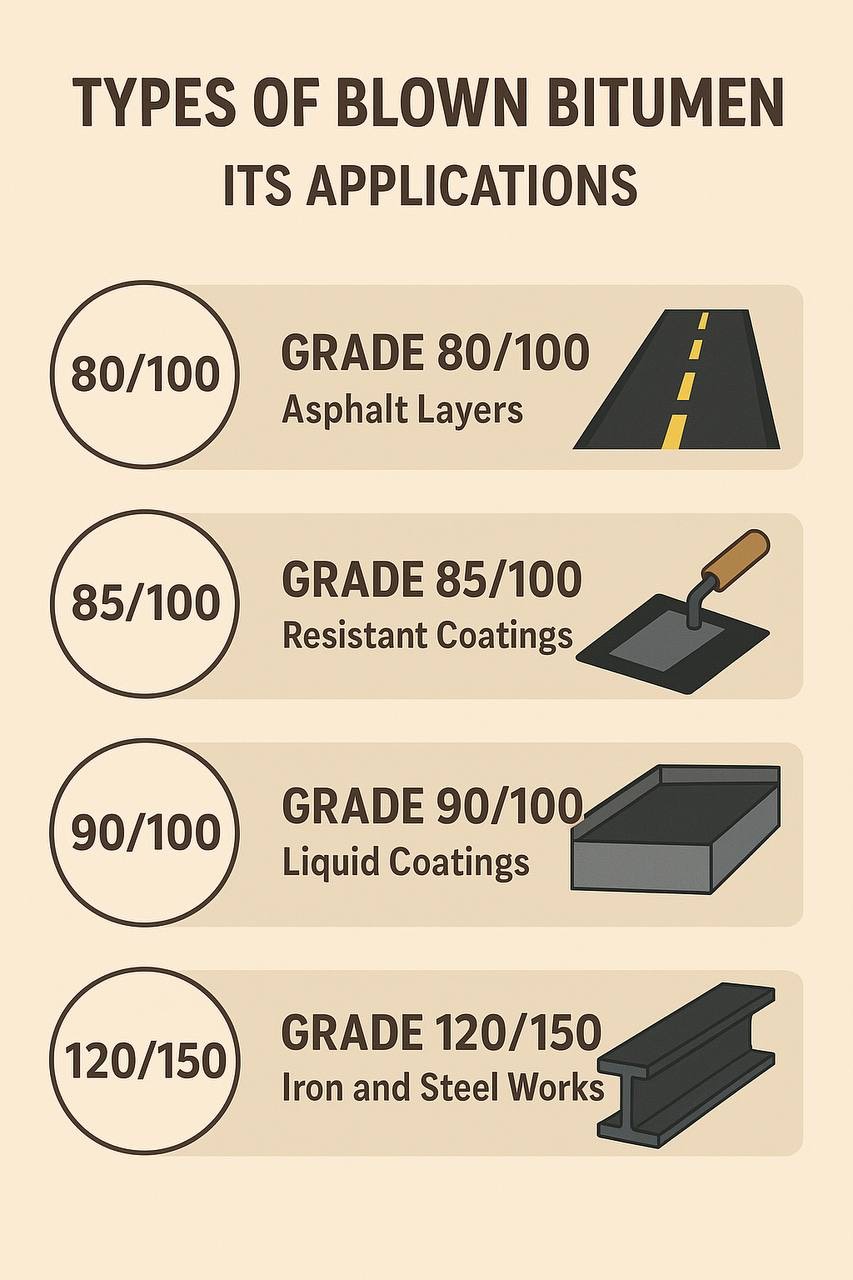

Due to its unusual properties, oxidized bitumen finds application in a very wide range of uses, including:

•Waterproofing and Roofing Membranes: Ideal for waterproofing layers, bonding membranes, and insulation rolls.

•Industrial Flooring and Mastics: Used in industrial building floor flooring due to its high resistance to chemicals.

•Anti-Corrosion Layers and Pipeline Coatings: Applied as anti-corrosion coating in petroleum and gas pipelines.

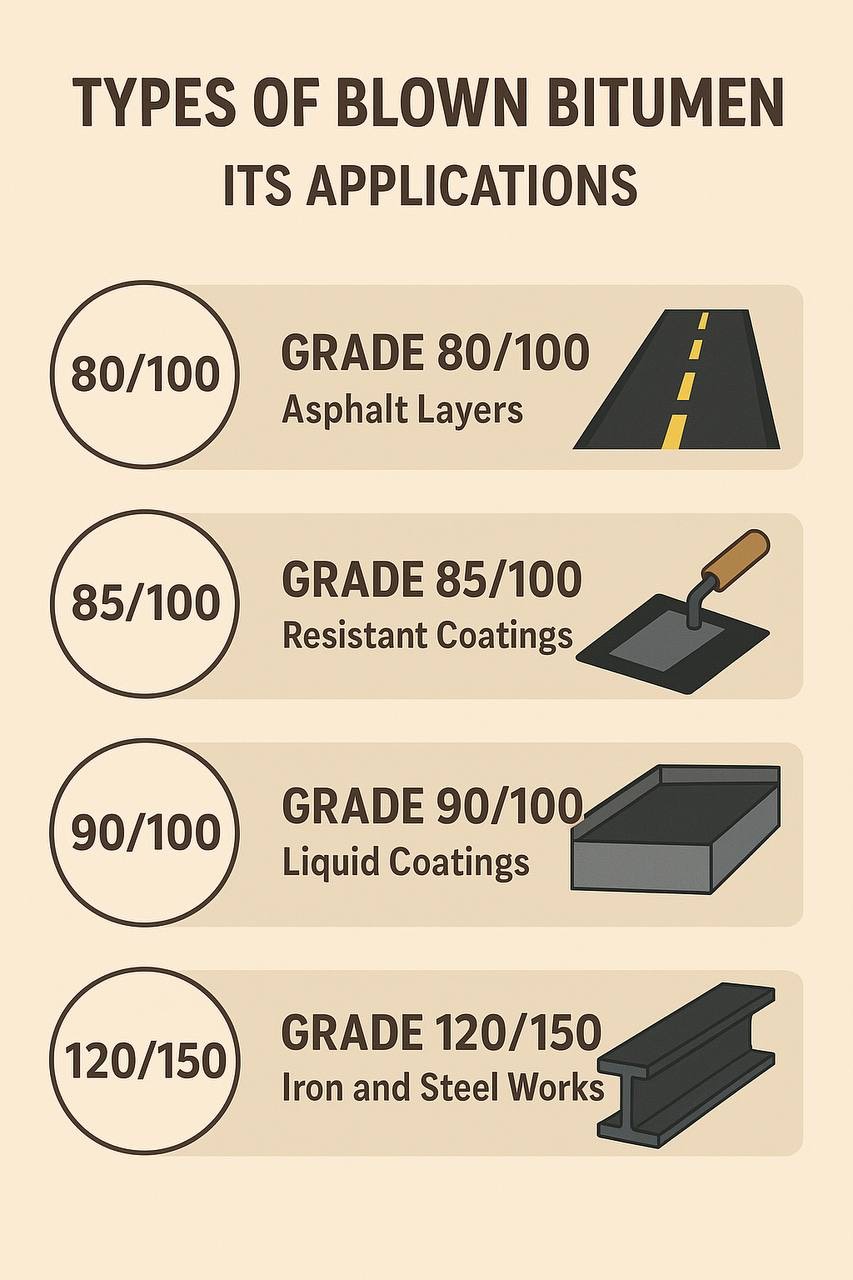

• Road Construction: While blown bitumen is not typically present in normal HMA asphalt mixes (due to hardness in some grades), it is used in specialized mixes and specialty applications.

• Electrical and Electronics Industry: Used from time to time in laminated boards, cable sealing, and electrical connection insulation.

Advantages and Disadvantages of Blown Bitumen

Advantages:

• High strength and high-temperature resistance

• Excellent chemical and water resistance

• Improved adhesion

• Useful in protective and water-repellent coatings

Disadvantages

•Increased brittleness or reduced flexibility at very low temperatures (in some grades)

Technical Factors before Blown Bitumen Application

•Grade Selection (e.g., R85/25 or R90/15) must be made based on project needs such as thermal resistance, mechanical properties, climatic specifications, and material compatibility.

•Process Control (time, temperature, and air flow rate) must be maintained to get desired specifications.

•Compatibility Tests are to be conducted, particularly while blending with other materials (resins, additives, fibers).

: